Ինչպես են աշխատում ավտոմատ բլոկերի մեքենաները. հիմնական տեխնոլոգիան և դիզայնը

Ինչ է ավտոմատ բլոկերի մեքենան

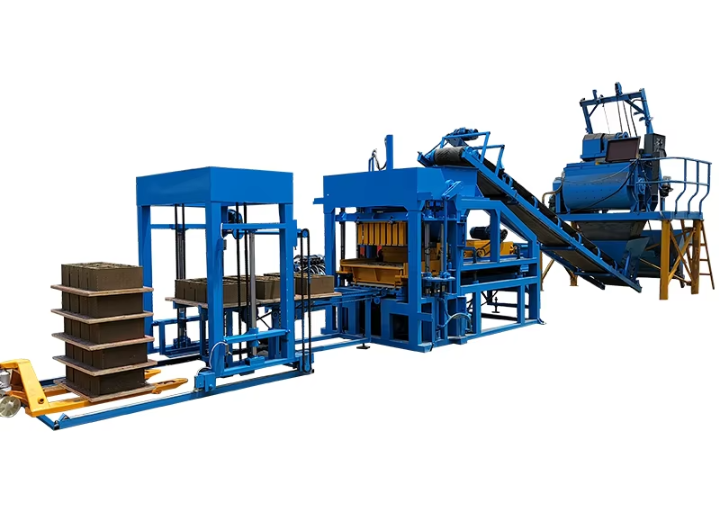

Ավտոմատ խորշաքարի արտադրման մեքենաները գործում են որպես լրիվ արտադրական համակարգեր, որտեղ նյութերը ինքնաբերաբար լցվում, խառնվում, ձուլվում և կույտ են դառնում՝ առանց օպերատորների անմիջական մասնակցության: Ժամանակակից շատ համակարգեր հիդրավլիկ սեղմիչներին միացնում են PLC կառավարման համակարգեր՝ ձուլման ընթացքում ճնշումը հաստատուն պահելու համար: Այս լրիվ ավտոմատացված համակարգերի և կիսաավտոմատ համակարգերի տարբերությունը ինչ է՞: Երբ ամեն ինչ աշխատում է ավտոմատ ռեժիմով, սովորաբար խորշաքարերի խտության և իրական չափսերի համազանգվածությունը կազմում է մոտ 95-97%: Այս տիպի ճշգրտությունը շատ կարևոր է խոշոր շինարարական աշխատանքների համար, որտեղ նույնիսկ փոքր անհամապատասխանությունները կարող են հետագայում մեծ խնդիրներ առաջացնել:

Հուսալիության համար PLC կառավարման և հիդրավլիկ համակարգերի ինտեգրում

Երբ PLC ավտոմատացումը ձեռք ձեռքի է աշխատում հիդրավլիկ ուժի հետ, գործարանային հարկերում ամեն ինչ շատ ավելի հարթ է ընթանում: Այս ծրագրավորվող տրամաբանական կառավարիչները վերահսկում են տարբեր պարամետրեր, ինչպիսիք են խառնման հարաբերակցությունները, նյութերի հասունացման տևողությունը, ինչպես նաև վերահսկում են տատանումները մշակման ընթացքում: Նույն ժամանակ հիդրավլիկ համակարգը հզոր հարված է հասցնում՝ ապահովելով 150-ից 300 տոննա ճնշում, որն անհրաժեշտ է այդ բլոկները համապատասխանաբար ձևավորելու համար: Կոմբինացիան իրականում կրճատում է մարդկանց կողմից ձեռք բերված սխալները: Անցյալ տարի հրապարակված որոշ հետազոտություններ ցույց են տվել, որ այս կառուցվածքն օգտագործող գործարանները արտադրության ընթացքում կանգնեցումներ են ապրել մոտ 87 տոկոսով պակաս, քան հին ձևի ձեռնարկային մեթոդները՝ համաձայն Concrete Tech Journal-ի հայտնաբերումների:

Մեքենայի հզորությունն ու կառուցվածքը՝ կատարողականի հիմնարար որոշիչներ

Բարձր կատարողականությամբ մոդելները հասնում են մինչև 3,000 հատ ժամը՝ օպտիմալացված թրթռացող սեղանների և արագ ցիկլային ձուլման շնորհիվ: 2022 թվականի արդյունաբերական վերլուծությունը ցույց տվեց, որ ավտոմատ սարքավորումներ օգտագործող գործարանները 65% կրճատել են աշխատանքի ծախսերը՝ միաժամանակ կրկնապատկելով արտադրությունը: Հիմնական նախագծման գործոններն են՝

- Ձևերի համատեղելիություն 15+ տեսակի բլոկերի հետ (թույլ, հատակածածկ, փոխկապված)

- Էներգիայի վերականգնման համակարգեր, որոնք 22%-ով կրճատում են էլեկտրաէներգիայի սպառումը

- 360° սենսորային զանգվածներ, որոնք իրական ժամանակում հայտնաբերում են նյութի անհամապատասխանություններ

Բարձր ծավալով բետոնե բլոկերի արտադրության մեջ արտադրողականության աճ

Ավտոմատացման և տեխնոլոգիաների ինտեգրման միջոցով արտադրողականության աճ

Այսօրվա ավտոմատ բլոկների արտադրման սարքերը կարող են ամեն օր արտադրել 3-ից 5 անգամ ավելի շատ բլոկներ, քան աշխատողները՝ ձեռքով աշխատելիս: Գաղտնիքն այն է, որ դրանք օժտված են առաջադեմ ավտոմատացման հնարավորություններով: Ժամանակակից սարքավորումների մեծ մասը հիդրավլիկ պրեսների հետ միասին օգտագործում է ծրագրավորվող տրամաբանական կառավարիչներ (PLC)՝ սերվոմոտորներով ապահովված: Այս համադրությունը նվազեցնում է ցիկլերի միջև սպասման ժամանակը՝ պահպանելով բլոկների չափերի ճշգրտությունը: Պատկերացների արտադրության ոլորտում անցյալ տարի հրապարակված հետազոտությունների համաձայն՝ այն ձեռնարկությունները, որոնք ամբողջովին անցել են լիարժեք ավտոմատացմանը, հասել են ակնառու արդյունքների: Նրանք նվազեցրել են նյութերի թափոնները մոտ 18 տոկոսով, իսկ էներգանյութի ծախսերը՝ մոտ 22 տոկոսով, համեմատած այն արտադրամասերի հետ, որոնք դեռևս օգտագործում են կիսաավտոմատ սարքավորումներ: Բավական հասկանալի է, թե ինչու է այսօր շատ արտադրողներ անցնում այս տեսակի սարքավորումներին:

Ավտոմատ սարքերի արդյունավետությունն ու արտադրողականությունը ձեռքով արտադրման տարբերակների համեմատ

| Ձեռքով արտադրություն | Ավտոմատ մաքնիններ | |

|---|---|---|

| Օրական արտադրություն (ստանդարտ բլոկներ) | 800–1,200 հատ | 4,800–6,000 հատ |

| Պարտադիր է աշխատանք | 8–12 աշխատող | 1–3 օպերատոր |

| Շաբաթօրյա արդյունավետություն | 58–67% | 89–94% |

Առաջատար արտադրողները հիմա օգտագործում են ինքնակարգավորվող ձևեր և արհեստական ինտելեկտով բարության հսկողություն, որը հնարավորություն է տալիս իրական ժամանակում օպտիմալացնել արտադրությունը՝ միաժամանակ շատ արտադրային գծերում:

Բետոնե խորշերի արտադրության ելք՝ իրական արտադրողականության չափում

Միջազգային խորշեղենի արտադրողների կոնսորցիումը հաղորդում է, որ ավտոմատ մեքենաները 24-ժամյա գործարկման ընթացքում հասնում են 92,4% արտադրողականության հաստատության, իսկ ձեռքով արված մեթոդների դեպքում այն կազմում է 54,1%: 2023 թվականի Քվանզոուի Մեգաշինարարության ցուցահանդեսում ավտոմատացված փաթեթավորման համակարգերը ցուցադրեցին 15,8 խորշ/րոպե մշակելու հնարավորություն՝ 312%-ով բարձր ձեռքով կատարված տեմպերից:

Ուսումնասիրություն. Ամբողջությամբ ավտոմատ խորշեղենի արտադրման մեքենաներին անցնելուց հետո արտադրողականությունը աճել է 300%

Կվանտանի Նախապատրաստված Շինարարական Լուծումները 2022 թվականի 2-րդ եռամսյակում իր ձեռքով աշխատող խորշեղենի արտադրությունը փոխարինեց ավտոմատացված մեքենաներով՝ հասնելով հետևյալ արդյունքների.

- 304% ավելի բարձր ամսական արտադրողականություն (47,200 – 144,600 խորշ)

- աշխատանքի արժեքի 91% կրճատում

- վեց ամսվա ընթացքում ստացված արտադրանքի 98,6% չափագրային համասեռություն

Այս փոխակերպումը հնարավորություն տվեց ընկերությանը միաժամանակ կատարել երեք խոշոր ենթակառուցվածքային պայմանագրեր՝ նախկինում անհնար համարվող մի բան ձեռքի աշխատանքի սահմանափակումների պայմաններում:

Ծախսերի և աշխատանքի կրճատում՝ արտադրանքի որակը չնվազեցնելով

Ավտոմատացված գործողությունների շնորհիվ աշխատանքի ծախսերի կրճատում

Ավտոմատ բլոկաշեն մեքենաները բետոնե բլոկների արտադրության մեջ վերացնում են ձեռքի աշխատանքի 85%-ը՝ ինտեգրված սնուցման, խառնման և ձուլման գործընթացների շնորհիվ: Արդյունաբերական հետազոտությունները ցույց են տալիս, որ գործարանները, որոնք օգտագործում են այդ համակարգերը, աշխատակազմի պահանջարկը նվազեցրել են 12-ից մինչև 2 օպերատոր մեկ հերթի համար՝ պահպանելով 24/7 արտադրողականությունը: Սա ուղղակիորեն կապված է արդյունաբերական շինարարության ոլորտներում ժամական 42 դոլար կազմող միջին աշխատանքի արժեքի հետ:

Ավտոմատացման արդյունավետությունը երկարաժամկետ արտադրական ցիկլերի ընթացքում

Չնայած ձեռքի բլոկների արտադրությունը մեկ միավորի համար ներառում է 8,50 դոլար աշխատանքի ծախսեր, ավտոմատացված համակարգերը 5 տարվա ընթացքում այն իջեցնում են մինչև 1,20 դոլար մեկ միավորի համար: 680% ROI (վերադարձի ցուցանիշ) բազմապատկիչը բխում է հետևյալից.

- 90%-ով նյութի կորուստների կրճատում՝ ճշգրիտ ծավալային կառավարման շնորհիվ

- 40%-ով ցածր էներգասպառում կիսաավտոմատ մոդելների համեմատ

- Գրեթե զրոյական վերամշակման դրույք՝ (98,4% առաջին անցման ելքը Բրազիլիայի նախապատրաստված փորձարկումներում)

Վեճի վերլուծություն. Բարձր սկզբնական ներդրում ընդդեմ երկարաժամկետ խնայողությունների

Քնարարները շեշտում են արդյունաբերական կարգի ավտոմատ բլոկներ արտադրող մեքենաների 185,000–420,000 դոլար սկզբնական արժեքը: Այնուամենայնիվ, Մալայզիայի գործարանների շահագործման տվյալները ցույց են տալիս, որ արտադրելով ≥4,000 բլոկ/օր դեպքում վերադարձը տեղի է ունենում 14–18 ամիս ընթացքում: 7 տարվա ընթացքում ավտոմատացված կառույցները տալիս են 2,7 միլիոն դոլար մաքսային խնայողություն՝ ձեռքով արտադրված տարբերակների համեմատ՝ ցուցադրելով համոզիչ երկարաժամկետ արժեք:

Կառուցվածքային ամբողջականության և որակի համապատասխանության ապահովում մասշտաբային արտադրության դեպքում

Բլոկների համապատասխանությունն ու որակը. Ինչպես ավտոմատացումը նվազեցնում է տարբերությունները

Բլոկների արտադրման մեքենաները, որոնք ծրագրավորված են ճշգրիտ նյութերի հարաբերակցությամբ և ճնշման կարգավորումներով, զգալիորեն կրճատում են մարդկային սխալները: Այս ավտոմատացված համակարգերը սովորաբար արտադրում են բլոկներ՝ խմբերի միջև խտության տարբերությունը 6%-ից պակաս լինելով, որը զգալիորեն լավագույնն է այն մոտ 23% տարբերությունից, որը տեղի է ունենում, երբ աշխատողները նյութերը խառնում են ձեռքով: Ժամանակակից սարքավորումները սուզգեր են ներդրված սենսորներով, որոնք ստուգում են հումքի հաստությունը՝ ըստ արտադրական գործընթացի: Երբ սենսորները հայտնաբերում են որևէ անսաղմնամբուխտ, այս սենսորները ավտոմատ կերպով կարգավորում են ջրի պարունակությունը՝ ապահովելով բետոնի աշխատանքային հատկությունները ամբողջ արտադրական գործընթացի ընթացքում: Ի՞նչ արդյունք: Բլոկներ, որոնք հասունանում են համաչափ տեմպերով և պահպանում են մոտ 1,5 մմ-ի սխալ իրենց նախատեսված չափերից: Արտադրողների համար այս տեսակի համաչափությունը նշանակում է ժամանակի ընթացքում ավելի քիչ թափոններ և կորցրած նյութեր:

Որակի վերահսկման մեխանիզմներ ավտոմատ բլոկների արտադրման մեքենաներում

Արտադրության ընթացքում իրականացվում է երեք շերտային որակի ստուգում.

- Հումքի ստուգում՝ էլեկտրամագնիսային առանձնացուցիչների միջոցով, որոնք հեռացնում են խառնուրդների 99,8%-ը

- Խմբակում ընթացքում սեղմման ուժի հսկում (±2% ճշգրտությամբ)

- Վերջնական բլոկների Մանր ճեղքերի հայտնաբերում ինֆրակարմիր սկանավորմամբ (0,1 մմ հայտնաբերման հնարավորությամբ)

Ինժեներական որակի վերահսկման լավագույն պրակտիկաների համաձայն՝ այս բազմաստիճան ստուգումը 87%-ով կրճատում է թերությունների քանակը համեմատած մեկ կետային ստուգման համակարգերի հետ

Արդյունաբերական պարադոքս՝ Ավելի բարձր արագությունը չի վտանգում կառուցվածքային ամրությունը

Չնայած ընդունված տրամաբանությունը ասում է, որ ավելի արագ արտադրությունը վտանգում է որակը, սակայն ժամանակակից ավտոմատ մեքենաները այս խնդիրը լուծում են հետևյալ եղանակով.

- Դինամիկ ճնշման կարգավորում՝ փոխհատուցելով նյութի հոսքի տատանումները

- Ճշգրիտ թրթռացող սեղաններ՝ պահպանելով խառնուրդի հավասարաչափ բաշխումը 1200 ցիկլ/րոպե հաճախականությամբ

- ԱԻ-ով օդային անթափ տարածությունների հայտնաբերում՝ ապահովելով 6–8% օպտիմալ թափանիշ

Վերահսկվող փորձարկումները ցույց են տվել, որ 2000 հատ/ժամ արագությամբ արտադրված բլոկները դիմադրում են 18,5 Ն/մմ² սեղմման ամրության՝ գերազանցելով ձեռքով արտադրված շարքերը 14%-ով

Տվյալ. Ավտոմատացված գործարանում Մալայզիայում հասնում է 98,6% համասեռության

Ջոհոր Բահրուի գործարանը գրանցել է արտադրանքի 98.6% համապատասխանություն եռամսյակը մեկ արտադրված 11 միլիոն բլոկների վրա՝ PLC-կառավարվող չորացման խցիկների և ավտոմատացված դարսման համակարգերի ներդրումից հետո: Այս հուսալիությունը նպաստել է գործընկերային ենթակառուցվածքային նախագծերի շինարարության ուշացումների 40%-ով կրճատմանը:

Մասշտաբավորում և ապագայի համար պատրաստվածություն ինտելեկտուալ, կայուն բլոկների արտադրությամբ

Ավտոմատ բլոկներ արտադրող մեքենաների մասշտաբավորումը աճող ձեռնարկությունների համար

Ավտոմատ բլոկներ արտադրող մեքենաները թույլ են տալիս արտադրողներին մեծացնել արտադրությունը օրական 5,000-ից մինչև 50,000 բլոկ՝ առանց սարքավորումների վերակառուցման։ Դրանց ստանդարտացված ձուլման համակարգերն ու ծրագրավորվող տրամաբանական վերահսկիչները թույլ են տալիս հեշտությամբ կարգավորել հզորությունը՝ ինչը կարևոր է ձեռնարկությունների համար, որոնք ընդլայնվում են նոր շուկաներում կամ կառավարում են սեզոնային պահանջարկի սրունքները։

Մոդուլային կազմավորումներ, որոնք թույլ են տալիս փուլ առ փուլ ընդլայնում

Ժամանակակից համակարգերը օգտագործում են լրակազմ բաղադրիչներ, որոնք թույլ են տալիս օպերատորներին արտադրողականությունը 20% բարձրացնել փուլ առ փուլ: 2024 թվականի արդյունաբերական վերլուծությունը ցույց տվեց, որ մոդուլային ավտոմատ բլոկաշեն մեքենաներ օգտագործող գործարանները ստանում են 40% ավելի արագ դրամայնացման ցուցանիշ՝ փուլ առ փուլ ներդրումների շնորհիվ: Այս կազմաձևումները նախնական ծախսերը 35% կրճատում են լիակարգ հզորությամբ տեղակայումների համեմատ, միաժամանակ պահպանելով ապագայում մոդեռնացման պատրաստ լինելու հնարավորություն:

Ավտոմատացում և տեխնոլոգիաների ինտեգրում. IoT և կանխատեսողական սպասարկում

Ինտեգրված IoT սենսորները իրական ժամանակում հետևում են սեղմման ուժերին և թրթռոցների օրինաչափություններին՝ ապահովելով.

- Կանխատեսողական սպասարկման զգուշացումներ 72 ժամ առաջ բաղադրիչների անսարքությունից առաջ

- Ավտոմատ նյութերի հարաբերակցության կարգավորումներ հումքի որակի տատանումների ընթացքում

- Հեռահար կատարողականի հսկում մի քանի արտադրական հարթակներում

Էներգախնայող մոդելներ՝ նվազեցնելով էկոլոգիական հետքը

Հաջորդ սերնդի մեքենաները կրճատում են էներգախնայողությունը 25-30% -ով՝ օգտագործելով ռեգեներատիվ հիդրավլիկ համակարգեր և օպտիմալացված թրթռացման ալգորիթմներ: Արդյունաբերության առաջատար ընկերությունները այժմ օգտագործում են 15-20% վերամշակված խառնուրդ աղբյուրներ տաքստերում՝ ամրությունը չնվազեցնելով, ինչը համապատասխանում է LEED սերտիֆիկացման պահանջներին կայուն շինարարական նախագծերի համար:

Շուկայի հետազոտություն. Գլոբալ տեղաշարժ դեպի ինտելեկտուալ, միացված տաքստերի արտադրության գծեր

2024 թվականին հարցմանը մասնակցած տաքստերի արտադրողների 68%-ից ավելին իրականացնում է արտադրության հետևում ամպի վրա, իսկ ինտելեկտուալ ավտոմատ տաքստերի արտադրման մեքենաները դառնում են գործողությունների հիմնական հիմքը: Այս կապը հնարավորություն է տալիս իրականացնել «ճիշտ ժամանակին» տաքստերի մատակարարման համակարգեր, որոնք մեծ ենթակառուցվածքային նախագծերում պահեստային ծախսերը կրճատում են մինչև 18 դոլար/մ²:

Հաճախ տրվող հարցեր

Ո՞րն է ավտոմատ տաքստերի արտադրման մեքենաների օգտագործման հիմնական առավելությունը:

Ավտոմատ բլոկերի արտադրման մեքենաները առաջարկում են բարձր ճշգրտություն և արդյունավետություն բլոկերի արտադրության մեջ, ինչը կրճատում է աշխատանքի ծախսերը և ավելացնում արտադրության համազանգվածությունը:

Ինչպե՞ս են ավտոմատ տաքստերի արտադրման մեքենաները կրճատում աշխատանքի ծախսերը:

Նրանք ավտոմատացնում են կերառատումը, խառնումը և ձուլումը նման կարևոր գործընթացները՝ կրճատելով մեծ աշխատակազմի կարիքը և սովորաբար պահանջում են միայն 1-3 օպերատոր յուրաքանչյուր հերթափոխում:

Ավտոմատ աղյուսակազմ մեքենաները արդյո՞ք շրջակա միջավայրի համար անվտանգ են:

Այո՛, նրանք նախագծված են ավելի քիչ էներգիա օգտագործելու համար և կարող են օգտագործել վերամշակված նյութեր, աջակցելով կայուն շինարարական պրակտիկաներին:

Ինչպիսի՞ն է ավտոմատ աղյուսակազմ մեքենաներում ներդրումների տիպիկ դիմադրությունը:

Ներդրումների դիմադրությունը կարող է ձեռք բերվել 14-18 ամիս ընթացքում՝ ապահովելով զգալի երկարաժամկետ խնայողություններ ձեռքով արտադրության մեթոդների համեմատ:

Բովանդակության աղյուսակ

- Ինչպես են աշխատում ավտոմատ բլոկերի մեքենաները. հիմնական տեխնոլոգիան և դիզայնը

-

Բարձր ծավալով բետոնե բլոկերի արտադրության մեջ արտադրողականության աճ

- Ավտոմատացման և տեխնոլոգիաների ինտեգրման միջոցով արտադրողականության աճ

- Ավտոմատ սարքերի արդյունավետությունն ու արտադրողականությունը ձեռքով արտադրման տարբերակների համեմատ

- Բետոնե խորշերի արտադրության ելք՝ իրական արտադրողականության չափում

- Ուսումնասիրություն. Ամբողջությամբ ավտոմատ խորշեղենի արտադրման մեքենաներին անցնելուց հետո արտադրողականությունը աճել է 300%

- Ծախսերի և աշխատանքի կրճատում՝ արտադրանքի որակը չնվազեցնելով

-

Կառուցվածքային ամբողջականության և որակի համապատասխանության ապահովում մասշտաբային արտադրության դեպքում

- Բլոկների համապատասխանությունն ու որակը. Ինչպես ավտոմատացումը նվազեցնում է տարբերությունները

- Որակի վերահսկման մեխանիզմներ ավտոմատ բլոկների արտադրման մեքենաներում

- Արդյունաբերական պարադոքս՝ Ավելի բարձր արագությունը չի վտանգում կառուցվածքային ամրությունը

- Տվյալ. Ավտոմատացված գործարանում Մալայզիայում հասնում է 98,6% համասեռության

-

Մասշտաբավորում և ապագայի համար պատրաստվածություն ինտելեկտուալ, կայուն բլոկների արտադրությամբ

- Ավտոմատ բլոկներ արտադրող մեքենաների մասշտաբավորումը աճող ձեռնարկությունների համար

- Մոդուլային կազմավորումներ, որոնք թույլ են տալիս փուլ առ փուլ ընդլայնում

- Ավտոմատացում և տեխնոլոգիաների ինտեգրում. IoT և կանխատեսողական սպասարկում

- Էներգախնայող մոդելներ՝ նվազեցնելով էկոլոգիական հետքը

- Շուկայի հետազոտություն. Գլոբալ տեղաշարժ դեպի ինտելեկտուալ, միացված տաքստերի արտադրության գծեր

-

Հաճախ տրվող հարցեր

- Ո՞րն է ավտոմատ տաքստերի արտադրման մեքենաների օգտագործման հիմնական առավելությունը:

- Ինչպե՞ս են ավտոմատ տաքստերի արտադրման մեքենաները կրճատում աշխատանքի ծախսերը:

- Ավտոմատ աղյուսակազմ մեքենաները արդյո՞ք շրջակա միջավայրի համար անվտանգ են:

- Ինչպիսի՞ն է ավտոմատ աղյուսակազմ մեքենաներում ներդրումների տիպիկ դիմադրությունը: